Many people these days are in a rush to make their contribution towards reducing our footprint on the environment. In their want of everything to be cleaner and have a better life. One example is the packaging and tray-making industry. We're super excited to be a part of this awesome team at WONGS. So, to help us in producing trays on the eco-friendly manner part, we use a specific machine for making Pulp molding tray pulping line.

This manufacturing process is also called “Pulp Molding”, Paper moulding mold-Egg tray mold produce our tray. What is pulp molding? With paper, you can argue we are recycling in firat place. This boggles the mind, what is recycling collecting this used paper and converting that to new products? They break that down into pulp like sheet paper. This pulp is used to mould trays after making the pulp. After they are a bit hard we shape the trays, let them dry and we are all set to go.

These trays are 100% recycled paper as well, another effort of our commitment to lessening the impact on our environment. Compared to these previous tray manufacturing methods, which are the upper range at 30MJ/tray and 21L water/tray, we use energy and water in the lower range with the pulp moulding method. This is essential because saving on energy and water demands safeguards all the natural resources we are left with. Our WONGS trays actually biodegrade back into the earth. That way they do not fill landfills and harm the planet. Ours decompose within years, not centuries and will instead be breaking down in landfill for generations to come.

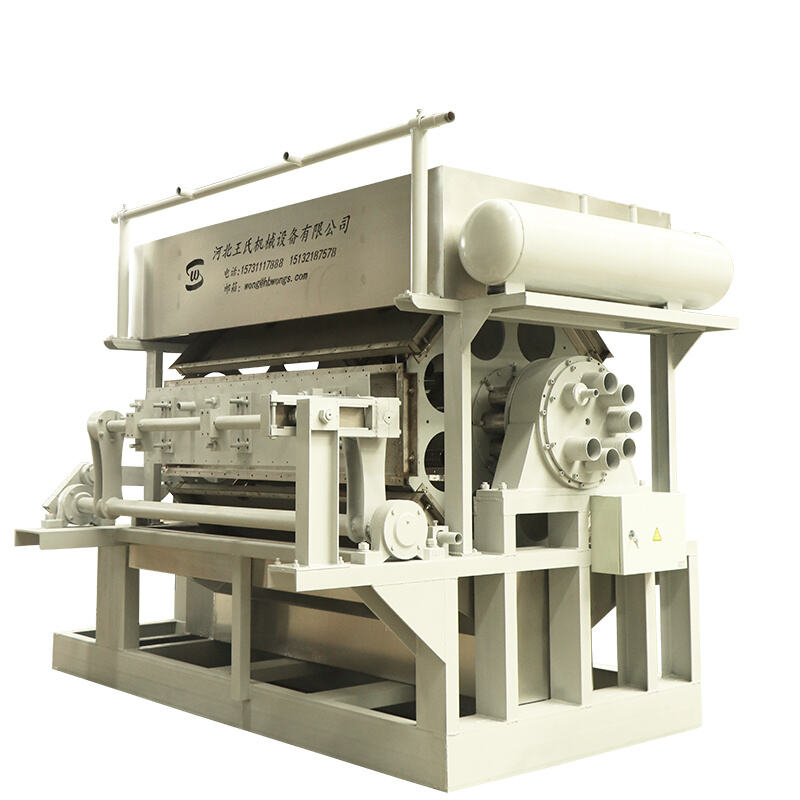

It is only then that we can make trays which have strength and durability. Thankfully for us here at WONGS we have an exceptionally gifted piece of machinery that does the pulp better than any other. It shreds the paper into tiny pieces, in order to create blown pulp which is consistent and uniformly thick resulting in trays. We require good strength at the end in our Egg box mold trays, to get that we need pulp of high quality.

Using our pulp molding machine, the psp tray will be much faster and healthier. And now in English We can pour more trays at twice the speed. This saves a lot of money for both us and our customers and simply allows us to deliver quality in the most cost efficient way. And of course, when we can produce our products for less it means we save money which in turn allows us to keep the prices low and makes buying options more convenient to everyone.

We understand everyone is different and so is their business, that's why here we customise the trays for you. That is why we offer custom-made pulp molding machine for the sake of their demand. Therefore, may the process change to confirm what our buyers thoughts are. Any shape or size of Fruit tray mold trays can be adapted to a different material if necessary. Our model is flexible for accommodating to customer specific requirements.

We have an independent R&D team and regularly update our equipment each year. Production of the product is automated, saving the cost of labor. The equipment is easy to operate and secure in production.Control system for equipment that is intelligent:Pulping Control of pulp ratio as well as concentration regulatorInverter-controlled form machine is easy to use and operate.Drying: temperature controllerPackaging: automatic packing machine with a single line of production for sorting, packing and counting.

More than 30 years of production and manufacturing expertisePre-sale service is available during the sale and after-saleTechnology for independent research and developmentOwn after-sales team and global technical assistanceBrand cooperation advantages: Omron, AirTAC, Hebei Motor, Renben Bearing, etc.

Our business is backed by a an established sales network and a highly skilled after-sales department. Basing its success on a unique mix of expertise and technological advancements, the paper pulp tray production line and molds for paper pulp are unique among other similar products. The number of customers using the country is increasing, and so are exports. As more and more people become buying our products, and they've been exported to Europe, South America and Southeast Asia, Africa, etc. across the globe. All customers are welcome, both old and new. to visit and negotiate with Hebei Wongs Machinery!

The space is 50,000 square metres. Three production workshops and a spray painting shop. We invested in CNC machining centers for laser cutting, bending and laser cutting lines, as well as other completely automated equipment.

Copyright © Hebei Wongs Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy