|

Place of Origin: |

Hebei, China |

|

Brand Name: |

Hebei Wongs |

|

Model Number: |

WS-4by8 |

|

Certification: |

CE |

|

Minimum Order Quantity: |

1 Set |

|

Price: |

USD100000 FOB Tianjin Xingang Port |

|

Packaging Details: |

In nude in container |

|

Delivery Time: |

50 days |

|

Payment Terms: |

30% deposit by T/T, 70% balance by T/T before delivery |

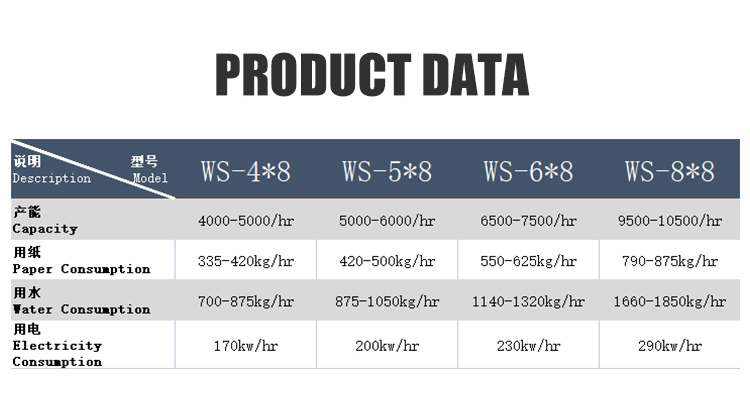

Model:WS4-8

Capacity: 4000-5000pcs/hr

Paper consumption: 335-420kg/hr

Water consumption:700-875kg/hr

Electricity consumption:150kw/hr

Drying way: brick dryer, metal dryer

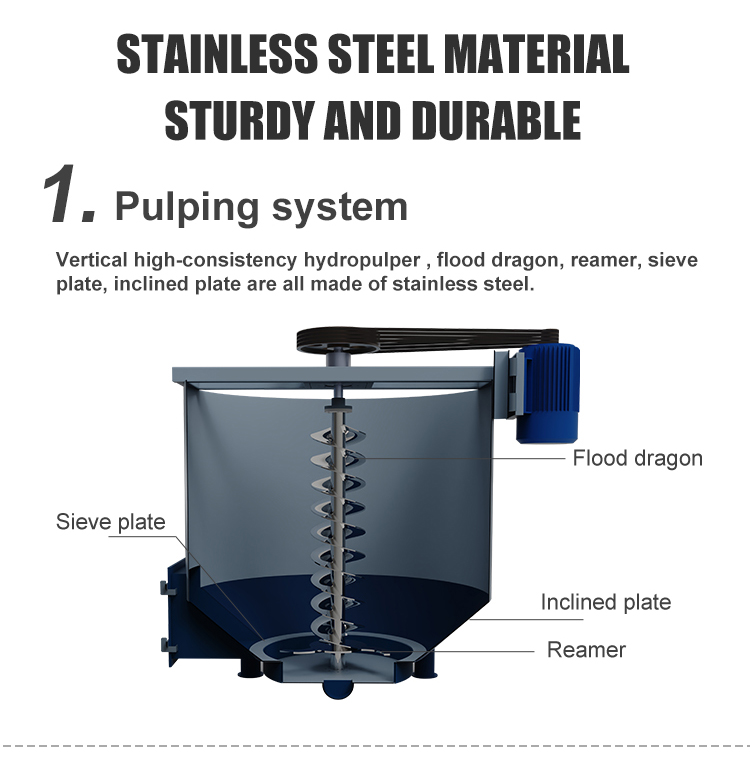

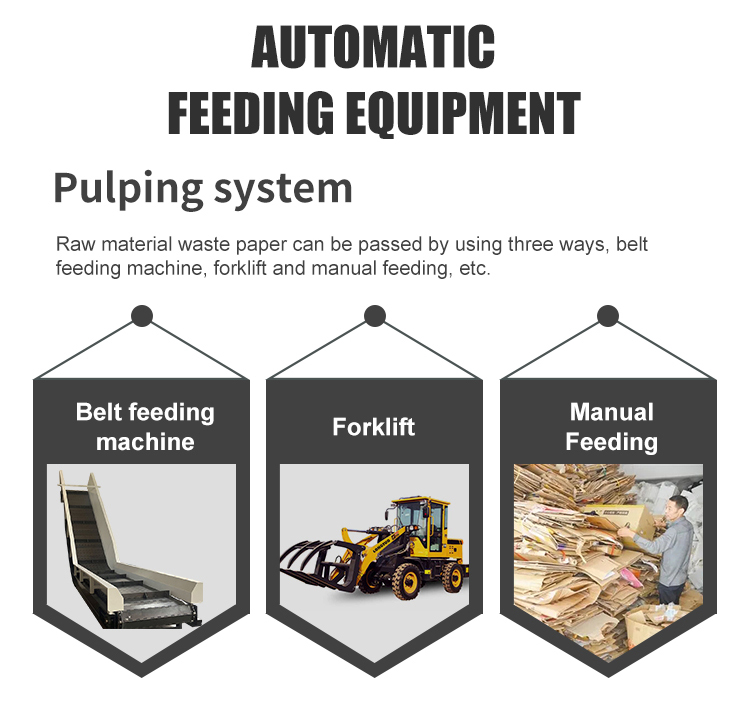

"Pulping system

(1) Put the raw material into the pulper and add an appropriate amount of water for a long time to stir the waste paper into pulp and store it in the storage tank.

(2) Put the pulp in the slurry tank into the pulping tank, adjust the pulp concentration in the pulping tank, and further stir through the agitator through the white water of the return pool and the thick slurry of the storage tank. After adjusting to the applicable pulp, put it into the feeding pool to be used in the molding system.

Equipment used: pulping machine, agitator, pulp pump, vibrating screen, pulp disintegrator

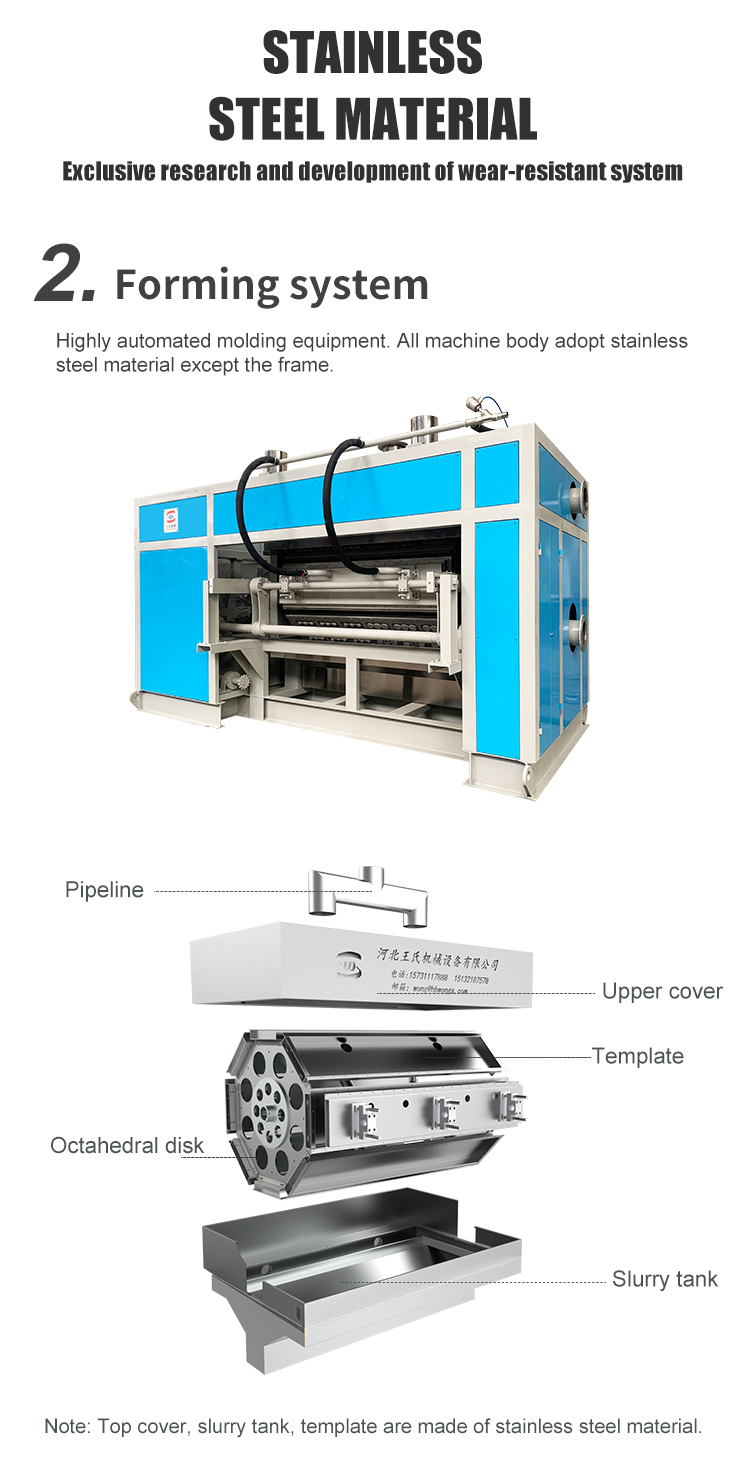

2. Forming system

(1) The pulp in the supply tank is supplied into the molding machine, and is adsorbed by the vacuum system, and the pulp is left on the mold by the mold on the equipment to be formed, and the white water is sucked and transported back into the pool through the vacuum pump.

(2) After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product is blown from the molding die to the rotary mold, and is sent out by the transfer mold.

Equipment used: molding machine, mold, vacuum pump, vacuum tank, pump, air compressor, mold cleaning machine

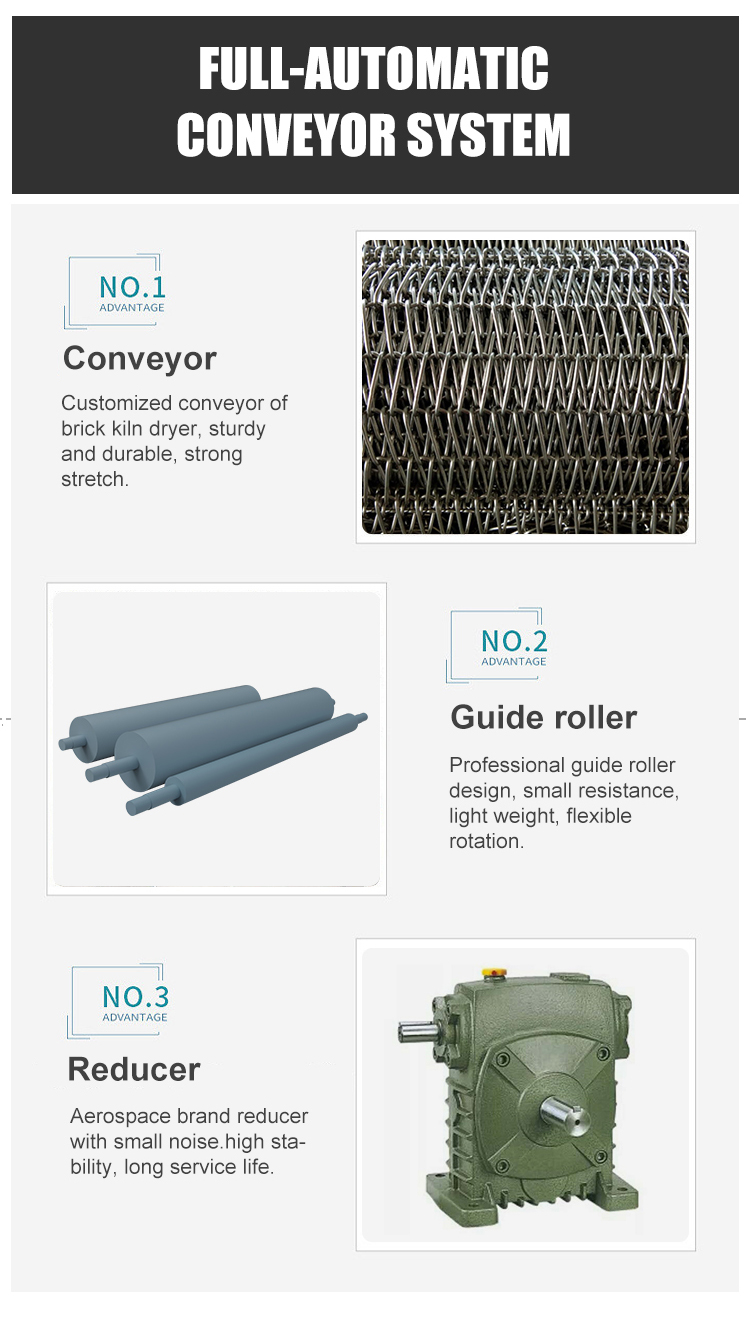

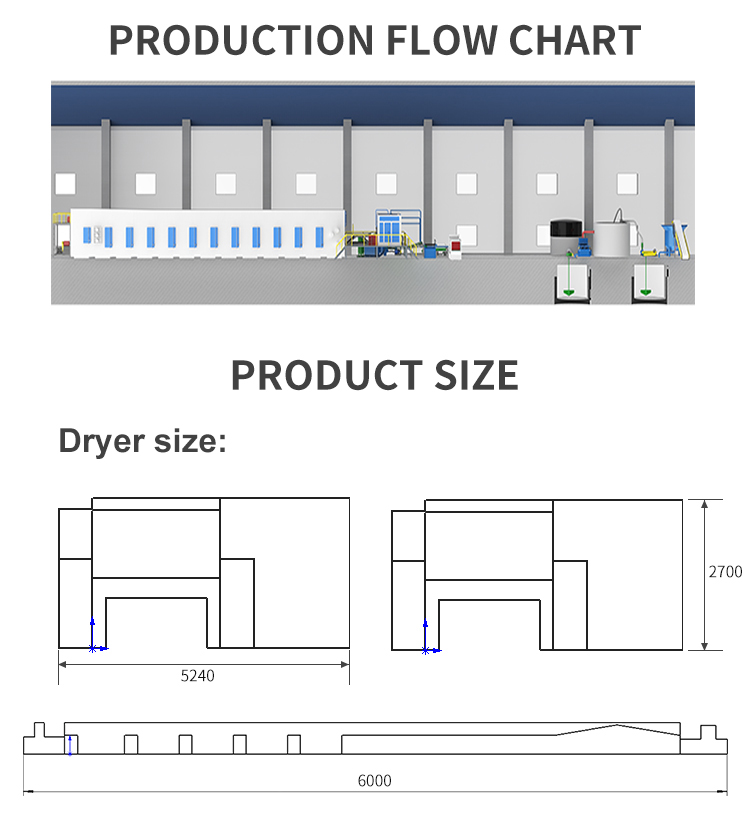

3. Drying system

(1) Natural drying method: The product is dried directly by weather and natural wind.

(2) Traditional drying: brick tunnel kiln, heat source can choose natural gas, diesel, coal, dry wood,A heat source such as liquefied petroleum gas.

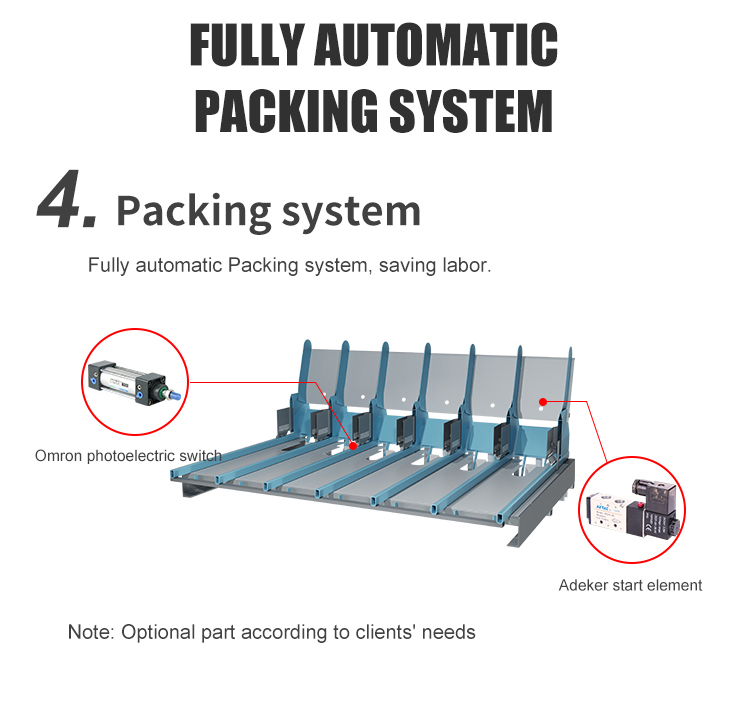

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy compared to transmission drying. The main heat source is clean energy such as natural gas, diesel oil, liquefied petroleum gas and methanol."

|

Full automatic Recycling Paper Pulp Egg Tray Molding Machine 4000pcs/hr |

|

|

Capacity |

4000-5000 pcs/hr |

|

Power |

120kw |

|

Mold |

32+4 pcs |

|

Template Size |

1.490m * 0.47m |

|

Operating speed |

21 times /min |

|

Space require |

40m * 15m |

|

Dryer |

Dry by brick dryer or multi layer metal dryer |

Egg tray making machine mainly uses waste paper,waste carton as raw materials. By smash pulp, vibrating pulp, grinding pulp and forming pulp, the forming machine adsorbs the pulp by vacuum type with some necessary chemicals. The equipment also can produce the followings: package for glass and ceramics, crafts, small machinery, electric products, toys paper egg tray machine and so on.

We have our own factory,we can provide quality guaranteed products and price.

1.High efficiency and low cost.

2.Easy operation and reduce labor force.

3.Low noice and Safety.

4.Environmental protection.

5.Large output,5000-7000 pieces per hour.

Advantages:

1) Full automatic running according to setting

2) Global famous brand of electric parts make stable running

3) Optimized design with new technology, leading to high efficiency

4) Perfect malfunction checkout system and motor protecting system guarantee safe running.

Copyright © Hebei Wongs Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy