|

Place of Origin: |

Hebei, China |

|

Brand Name: |

Hebei Wongs |

|

Model Number: |

WS-6by8 |

|

Certification: |

CE |

|

Minimum Order Quantity: |

1 Set |

|

Price: |

USD140000 FOB Tianjin Xingang Port |

|

Packaging Details: |

In nude in container |

|

Delivery Time: |

50 days |

|

Payment Terms: |

30% deposit by T/T, 70% balance by T/T before delivery |

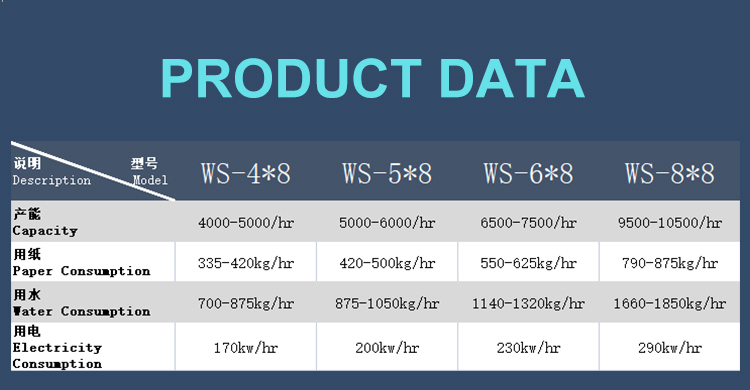

Model:WS6-8

Capacity: 6500-7500pcs/hr

Paper consumption: 550-625kg/hr

Water consumption:1140-1320kg/hr

Electricity consumption:230kw/hr

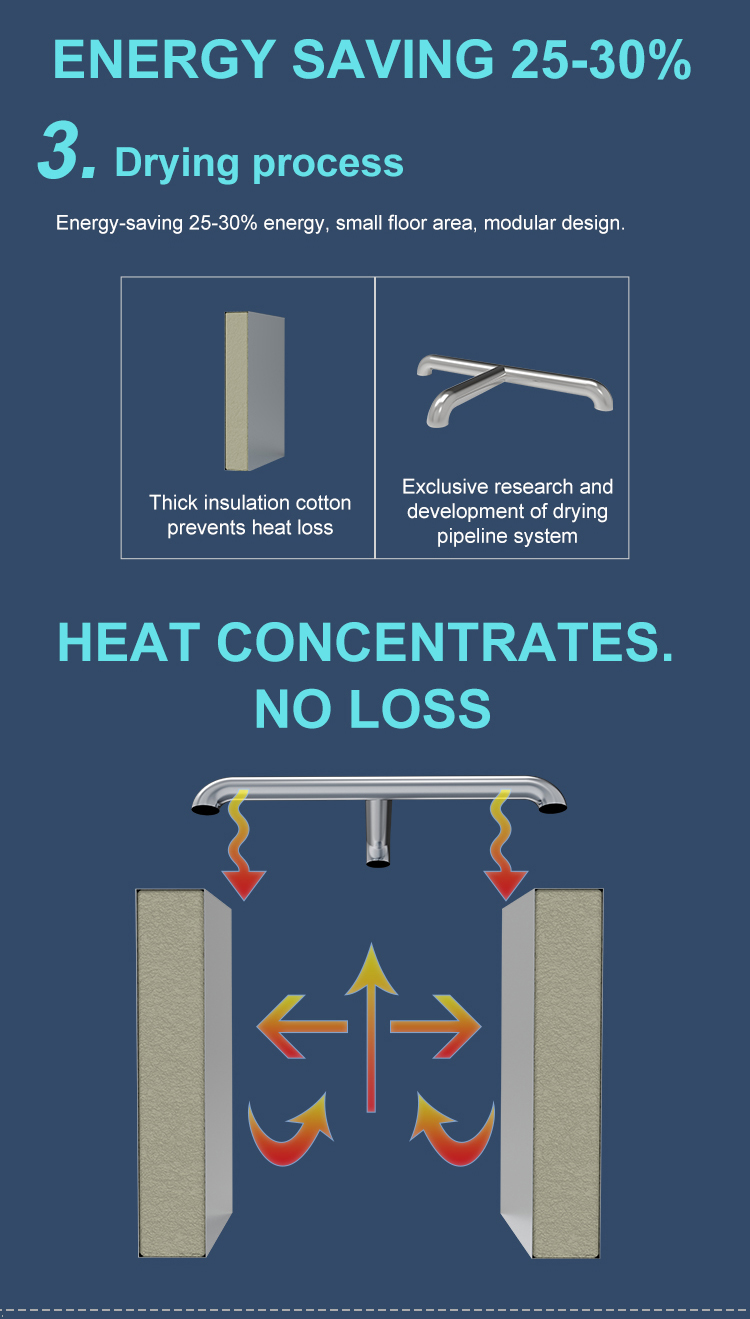

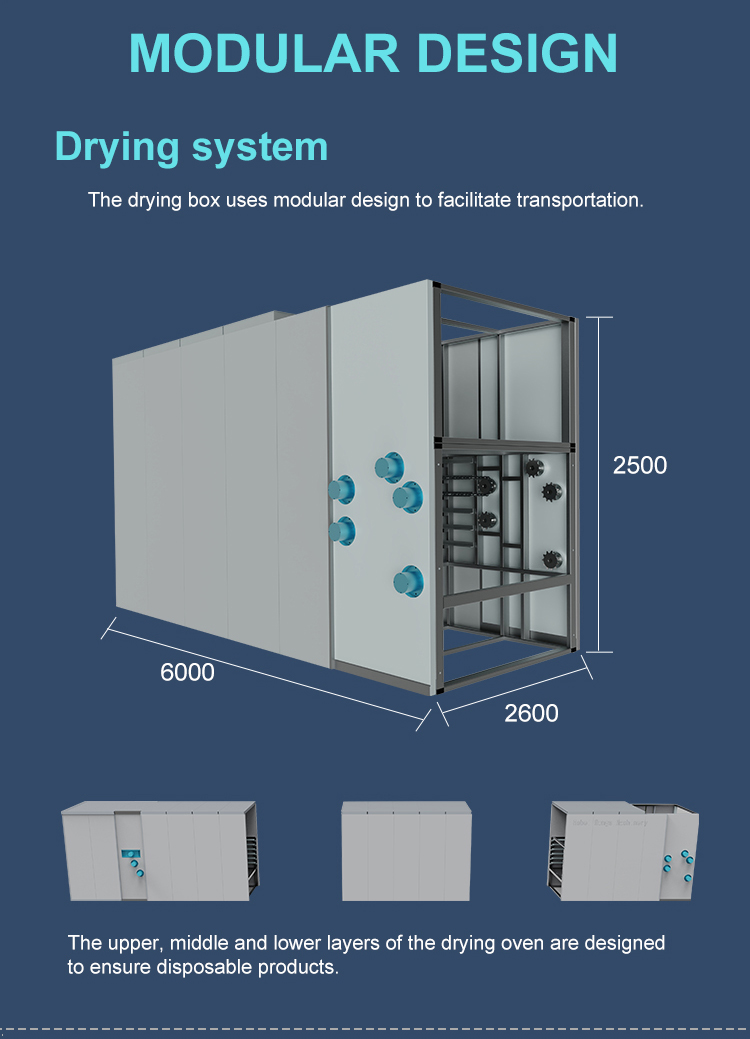

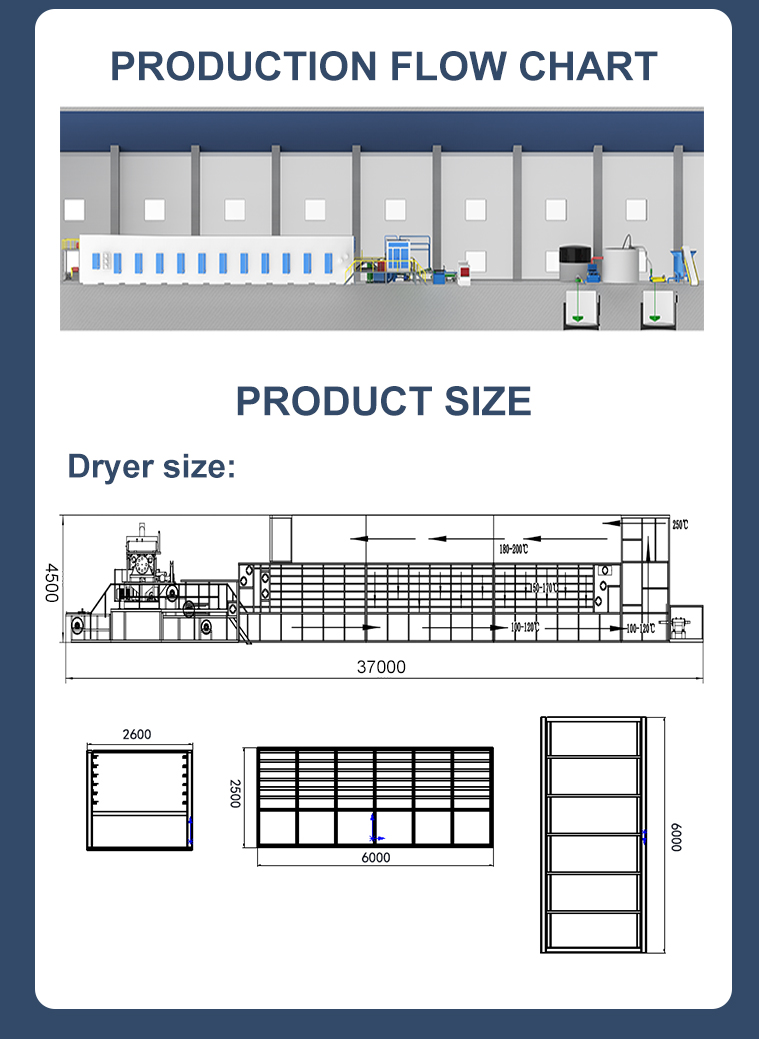

Drying way: brick dryer, metal dryer

|

Model |

WS-6by8 |

|

Capacity |

7000pcs/h |

|

No. of Molds |

48pcs forming molds plus 6 pieces transfer molds |

|

Labor needed |

7person per shift |

|

Machine color |

Can customize as per clients, like grey, silver, blue |

|

Template Size |

1550mm*470mm |

|

Voltage |

380V,voltage can be customized |

|

Power |

126kw |

|

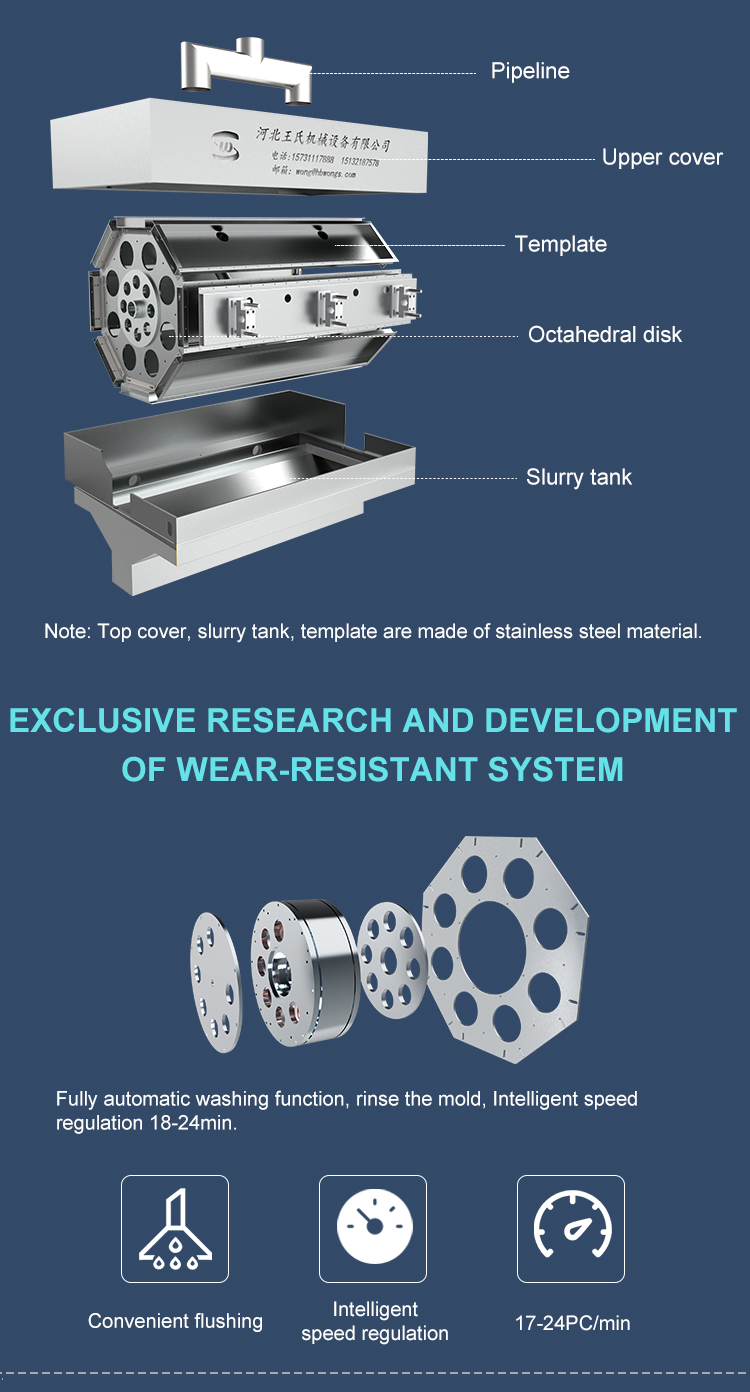

Rotary speed |

21 times per minute |

|

Drying method |

(1) Traditional drying: brick tunnel kiln, heat source can choose natural gas, diesel, coal, dry wood,A heat source such as liquefied petroleum gas. |

|

Delivery date |

50 days |

1) Simple type for producing smoothly and easy in installation and maintation.

2) Adopting advanced world famous brand components in electric parts and operation parts.

3) High power used in whole production line.

4) Running in a high automatization and intellectualization,no pollution, and water is recycled.

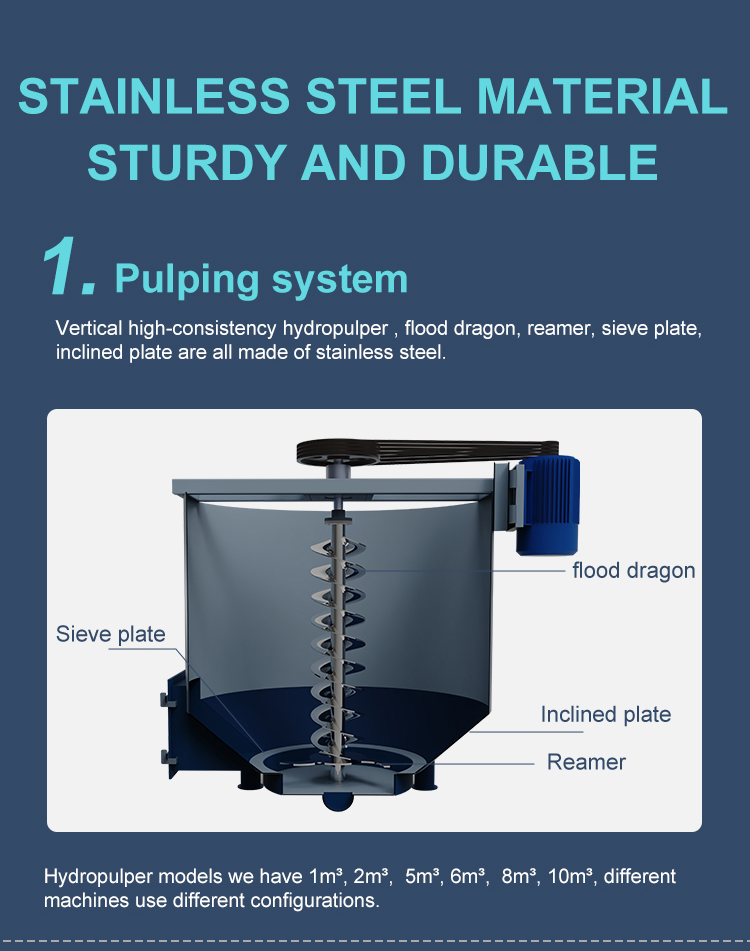

Pulp Moulding production line, which uses waste paper, cardboard, leftover material of paper mill, by hydraulic pulper, mix making a certain dense pulp, and pulp is absorbed by vacuum of special metal moulding to become wet products, through drying , and shaping to become finished products

Copyright © Hebei Wongs Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy