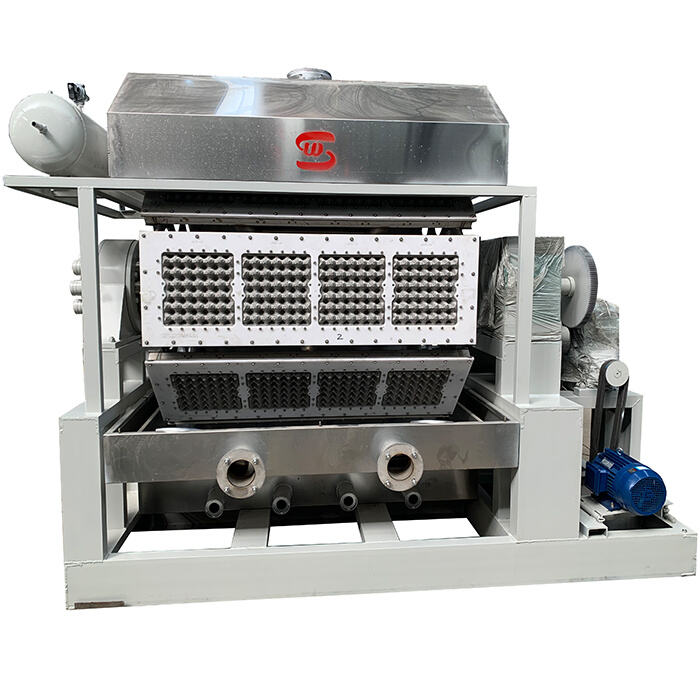

Plus, egg trays will help store eggs securely while they are transported from farms to the stores. Eggs are delicate, so when they travel, they break down quickly if not protected. That is why we need you some egg trays of good quality. Fast Egg Tray Making MachinesFor the production of many egg trays at a time in a fast and efficient manner, we require an efficient system for molding and drying of the same. The following is a special introduction to the egg tray making machine WONGS, here we will spread out some texts. It is a modern machine that works quickly and uses less energy so it makes the perfect addition to your egg tray production line.

Some crooks use a vacuum to remove the liquid plasma from fresh egg-mounted tubes so they can cover them with his fake puff collars, while others insert straws and burst out all of the eggs just so they look ready for market. An egg tray making machine that works in conjunction with fake eggs isn't the only way these thieves have figured out how to steal your money. Egg trays are both fast and durable It has a unique machine for moulding the trays in uniform size and shape. This is very crucial as the fit of the Egg box mold in the shipping containers will result in fewer runaway eggs from being broken during delivery. Uniform egg trays also help to support and protect the eggs more so that by the time consumers receive their eggs, they are still in perfect conditions.

WONGS has an automated production machine. Contractile sites with permission. Its sensors know when it is time for another tray. The sensors facilitate the remaining process by detecting when it is time to prepare another batch. Three more special parts work together to rapidly and automatically remove the trays from the molds — for quicker, more efficient processes overall. This is important, especially for large orders, to keep profitability from requiring to drop down (making more trays requires less quality).

The egg tray making machine from WONGS is easy to use as well as simple to maintain. There is a display screen that is used by the workers to monitor how each process is doing during production. This is a great feature since it allows operators to track the process as it progresses and — if needed — tweak any settings. The Industrial packing mold produced are food-safe and easy to wash, which is very crucial for their safety and usability in the culinary market.

The drying section in the machine is meant to be uniform and fast. It performs heating in unique mechanisms, which helps to spread heat evenly throughout the food so that all trays should dry at exactly the same time. In conclusion, drying in tandem is necessary for the simple fact that when every tray dries similarly all the trays are able to be packed at the same time which only serves to expedite production.

We designed the egg tray making machine that is energy saving and good for the environment. Its heat recovery component is able to reuse waste heat from the drying process, thereby reducing energy use. So, this is not only good for the environment but also foundations can save more money in energy bills. Also, the Paper moulding mold-Egg tray mold machine runs with less noise so that it is suitable for production facilities.

Covering an area of covering 50,000 square meters. Three production workshops are located on the premises, and one of them is a spray painting facility. Our company has invested in fully automated laser lines, totally automatic cutting lines, and fully automated bending machines, CNC machining centers, and numerous mold engraving machines to produce the most efficient equipment that can serve every client well.

Our business is backed by a a well-established sales network, and a seasoned after-sales staff. The paper pulp tray as well as paper pulp moulds are distinctive when compared to similar products as they're based on unique technologies and years of experience. Presently, our customers are scattered across the country, and the export volume of our products is increasing every year. Our products are valued by more and more customers and have been shipped to Europe, South America, Southeast Asia and Africa etc. All over the world. Hebei Wongs Machinery welcomes new and returning customers to visit our factory and talk with us!

Manufacturing and production expertise for more than 30 yearsPre-sale service, during the sale, and followingResearch and Development Technology-IndependentIt has its own after-sales support team, as well as global technical assistanceBrand cooperation advantages: Omron, AirTAC, Hebei Motor, Renben Bearing, etc.

We have an independent R&D team and upgrade our equipment every year. Production of products is fully automated, which reduces the cost of labor. Equipment is safe and simple to operate.Control of the equipment intelligent system:Pulping Intelligent control of pulp ratio and concentration regulatorControlled by an inverter, the form machine is simple to use and operate.Drying: Temperature controllerPacking: Automated packing machine using a single line for counting, picking and packing.

Copyright © Hebei Wongs Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy