|

उगम स्थान: |

हेबेई, चायना |

|

ब्रँड नाव: |

हेबेई वॉन्ग्स |

|

मॉडेल क्रमांक: |

WS-5by8 |

|

प्रमाणपत्रिका: |

सीई |

|

लव मर्यादित ऑर्डर क्वांटीटी: |

1 सेट |

|

मूल्य: |

एसडी १२०००० एफओबी टियांजिन शिंगांग पोर्ट |

|

पैकिंग माहिती: |

कंटेनरमध्ये नंदीत |

|

वितरण काल: |

५० दिवस |

|

भुगतान पद्धती: |

३०% प्रारंभिक भुगतान T/T वर, ७०% शेष T/T वाचवण्यापूर्वी |

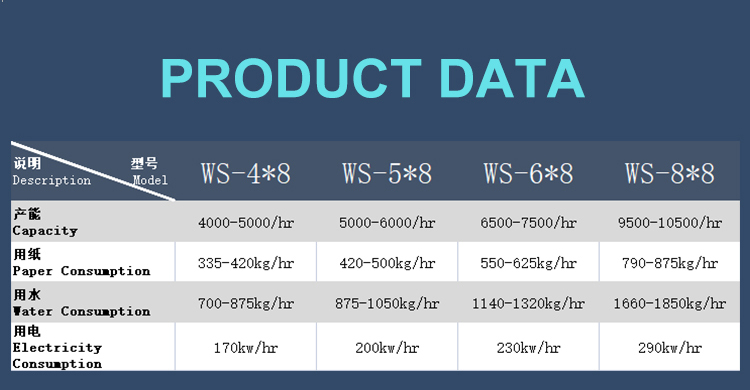

मॉडेल:WS5-8

क्षमता: 5000-6000पीस/घंटा

कागद खपत: 420-500किलो/घंटा

पाणीचा वापर: 870-1050 किलोग्रॅम/हॉर

विद्युत खपत: 180किलोवॅट/हॉर

शुष्कीकरण पद्धत: ब्रिक ड्रायर, मेटल ड्रायर

|

उत्पादनाचे नाव |

अंडा ट्रेझ यंत्र |

|

श्रम आवश्यकता |

7 व्यक्ती/शिफ्ट |

|

मॉडेल |

5by8 चक्राकार प्रकार |

|

क्षमता |

6000पीस/आय |

|

मोल्ड्सची संख्या |

४० पिस + ५ पिस |

|

यंत्राचा रंग |

ग्राहकांच्या मुळे तयार केला जाऊ शकतो |

|

टेम्पलेट आकार |

१२५०म्म*४७०म्म |

|

परिमाण |

३६००**२२५०*२५००म्म |

|

व्होल्टेज |

३८०वी, वोल्टता तयार केली जाऊ शकते |

|

शक्ती |

१२०क्व |

|

मॉल्ड सामग्री |

प्लाष्टिक किंवा एल्यूमिनियम, किंवा ABS |

|

फेर पेक्षा वेग |

२३ वार प्रति मिनिट |

|

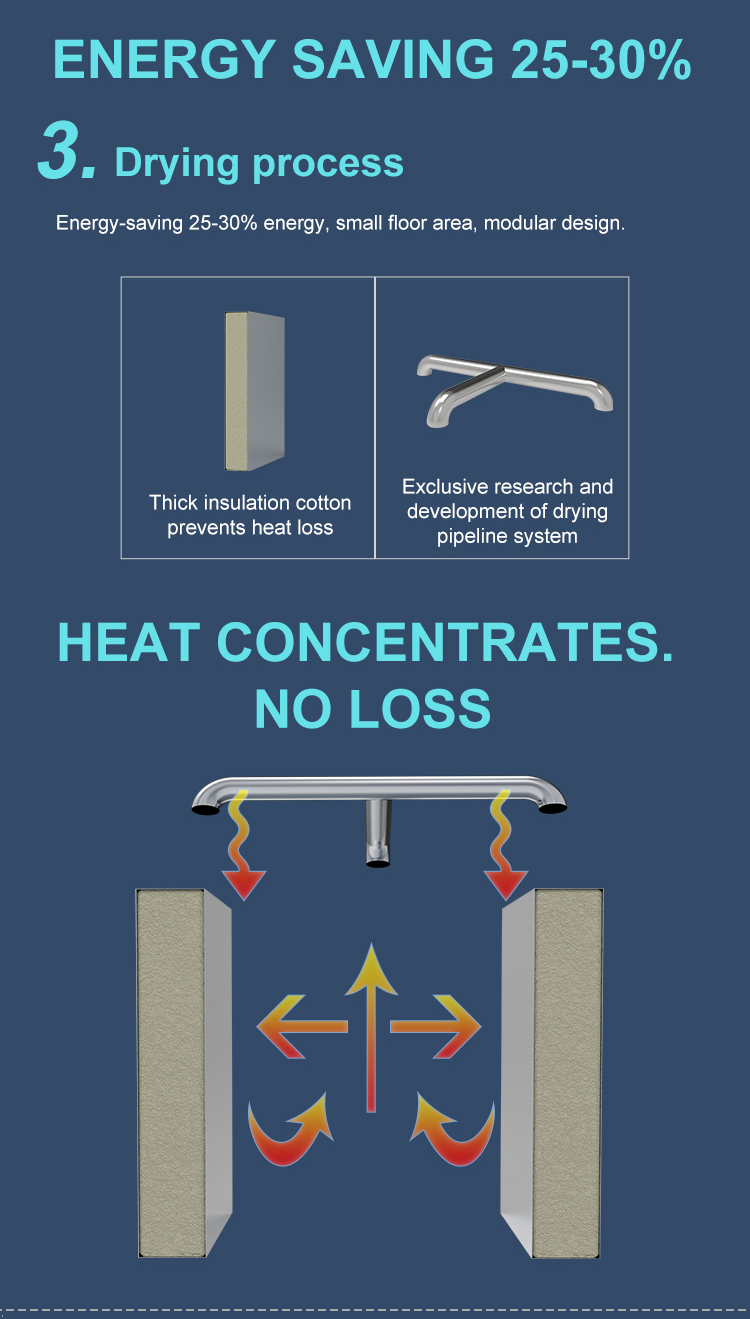

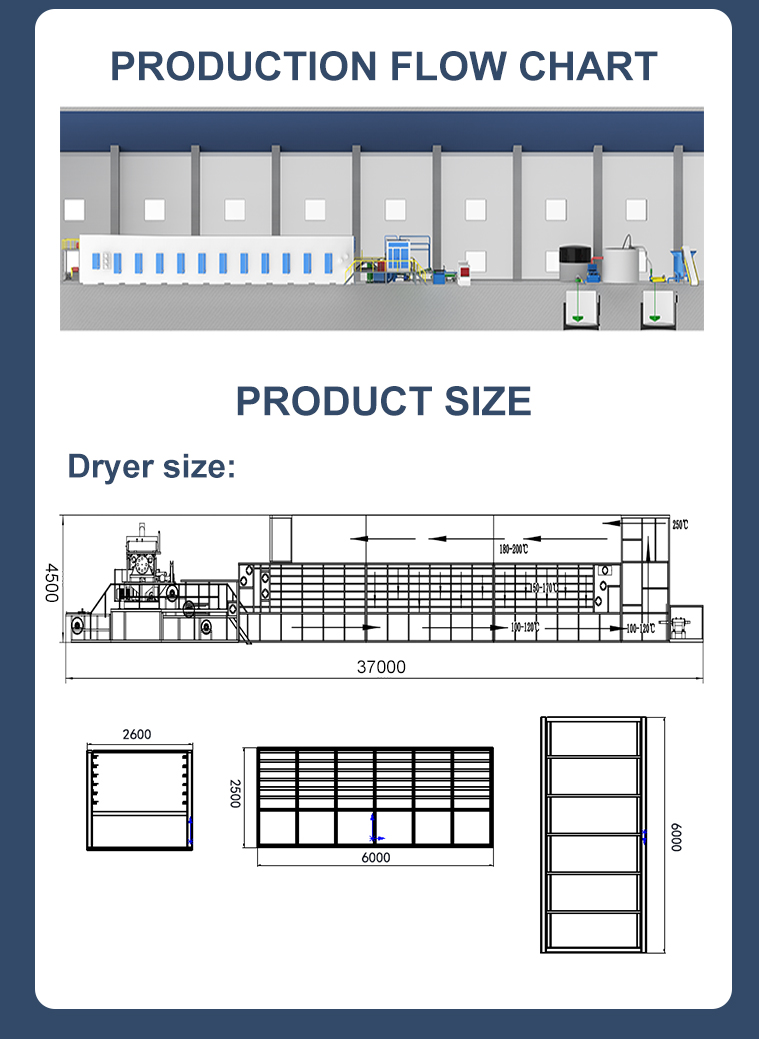

शुष्कीकरण पद्धत: (१) पारंपरिक शुष्कीकरण: बिल्लीची टनल किल्न, ऊष्मा स्रोत नैसर्गिक वायु, डिझेल, कोयला, शुष्क वृक्षाचा वापर करू शकते, तसेच द्रवीभूत पेट्रोलियम गॅस जसे ऊष्मा स्रोत. (२) नवीन बहुतह शुष्कीकरण लाइन: ६-तहांची धातूची शुष्कीकरण लाइन एक परिवर्तनात्मक शुष्कीकरणपेक्षा ३०% जास्त ऊर्जा बचवते. प्रमुख ऊष्मा स्रोत ही नैसर्गिक वायु, डिझेल तेल, द्रवीभूत पेट्रोलियम गॅस आणि मेथेनॉल जसे शुद्ध ऊर्जा आहे. |

|

पेपर मोल्डिंग उत्पादन लाइन, जी विफल पेपर, कार्डबोर्ड, कागद व्यावसायिक शेष घटक वापरून, हायड्रॉलिक पल्परद्वारे पल्प तयार करून खालीलप्रमाणे निश्चित घन पल्प तयार करते, आणि विशेष धातू मोल्डिंगद्वारे शून्यतेचा वापर करून ते गीले उत्पाद बनतात, त्यानंतर शुष्कीकरण आणि आकार देण्याने ते अंतिम उत्पाद बनतात.

1. उच्च उत्पादन

2. स्थापना आणि संचालन सोपे

3. मजबूत निर्माण

4. तापमानासाठी प्रतिसाद

5. प्रतिस्पर्धी मूळ्य

६. हिरवा: कागदची अपशिष्ट उत्पादन नाही

७. अंतिम उत्पादाची स्थिर गुणवत्ता (चांगले व जोरदार दिसणे, समान वजन आणि आकार)

८. जागेच्या ओळखावर आणि कमी निवड

९. एकूण प्राक-विक्री, विक्रीदरम्यान आणि पछाडीची सेवा.

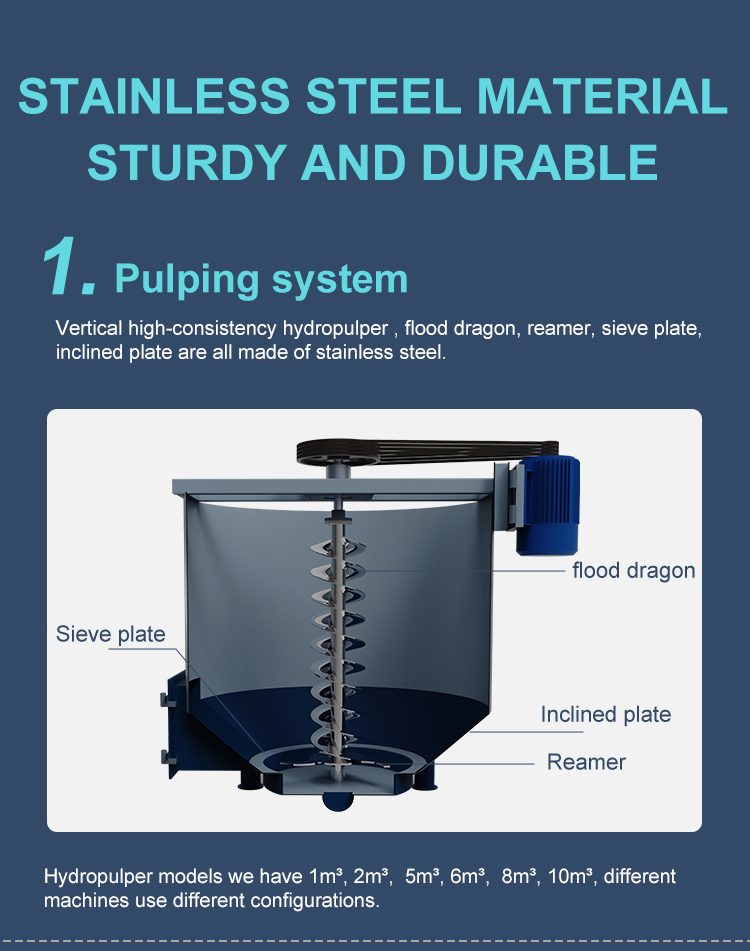

"पल्पिंग सिस्टम

(१) कचरा पेपर पल्परमध्ये ठेवून अनुपातपूर्वक पाणी ओळखून लांब काळ फिरवून पल्प तयार करा आणि ते स्टोरेज टॅंकमध्ये ठेवा.

(2) स्लरी टॅंकमधील पल्पला पल्पिंग टॅंकमध्ये ठेवा, पल्पिंग टॅंकमधील पल्प सांद्रता तयार करा, आणि पुनर्मिळ टॅंकच्या सफ़ेद पाण्याच्या माध्यमातून आणि स्टोरेज टॅंकच्या मोठ्या पल्पाच्या माध्यमातून अगितेटरद्वारे इतर फिरवा. उपयुक्त पल्पमध्ये तयार होऊन खालील पल्पला फीडिंग पूलमध्ये ठेवून मोल्डिंग सिस्टममध्ये वापर करा.

वापरल्या गेलेले उपकरण: पल्पिंग मशीन, अगितेटर, पल्प पंप, विब्रेशन स्क्रीन, पल्प डिसिन्टीग्रेटर

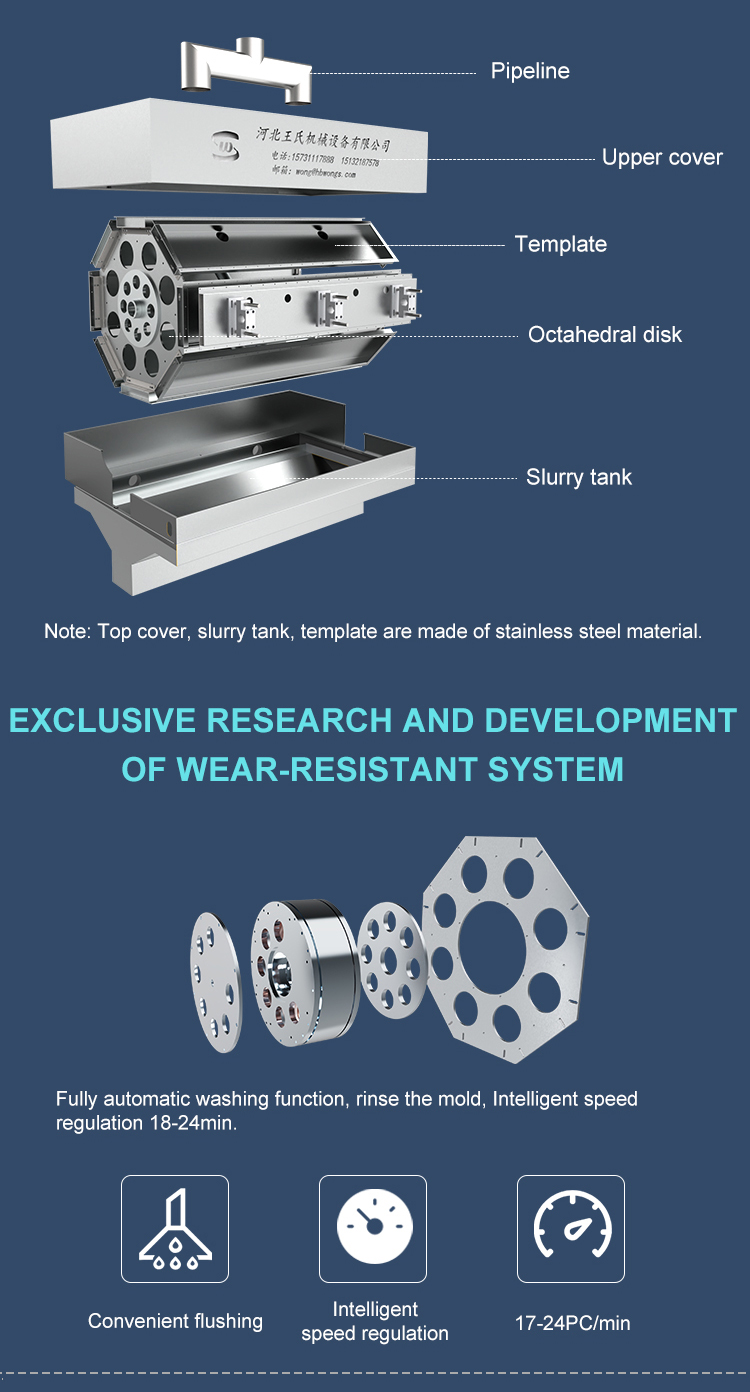

२. मोल्डिंग सिस्टम

(1) सप्लाय टॅंकमधील पल्पला मोल्डिंग मशीनमध्ये पुरवता, आणि वैक्यूम सिस्टमद्वारे त्याची अडस्त करा, आणि युनिटवरील मोल्डद्वारे पल्प मोल्डवर राखा जातो, आणि सफ़ेद पाणी वैक्यूम पंपद्वारे घेऊन पूलमध्ये परत भेट करण्यात येते.

(2) मोल्ड अडस्त करण्यानंतर, वायु कंप्रेसरच्या सकारात्मक दबावाने फेरफिर प्रोडक्ट प्रेस्सच्या वायुने मोल्डिंग डायमधून बाहेर फुटवतात, आणि ते रोटरी मोल्डमध्ये भेट करण्यात येतात, आणि फेरफिर मोल्डद्वारे बाहेर पाठवले जातात.

उपकरण वापरले: मोल्डिंग मशीन, मोल्ड, व्हॅक्युम पंप, व्हॅक्युम टॅंक, पंप, हवामार्ग कंप्रेसर, मोल्ड साफ करण्याची मशीन

3. सुखवण्याची पद्धत

(1) प्राकृतिक सुखवणे: उत्पादन आकाश आणि प्राकृतिक पवनाने सुखवले जाते.

(2) पारंपरिक सुखवणे: बिल्लीचा ट्यूनेल किल्न, तापमानाचा उपयोग करू शकता natural gas, डिझेल, कोयला, सूखी लकडू,liquefied petroleum gas यासारखे तापमान.

(3) नवीन बहु-तहाने सुखवण्याची लाइन: 6-तहाने धातूची सुखवण्याची लाइन ट्रान्समिशन सुखवण्यापेक्षा 30% जास्त ऊर्जा बचवू शकते. प्रमुख तापमानाचा उपयोग प्राकृतिक वायु, डिझेल तेल, liquefied petroleum gas आणि methanol यासारख्या शोधपूर्ण ऊर्जेचा आहे."

Copyright © Hebei Wongs Machinery Equipment Co.,Ltd All Rights Reserved - गोपनीयता धोरण