Kulokwenene, i-tray zakho zokugcina izithelo zikuthi zikhuse izithelo ngasemva kwezifundazwe ngenqanawe kwi-truck. Izithelo zingaphansi, ngakho lokhu ukuba zisendzela, zibhedele esikhathini sezinhloko ngakwesinye sizikhona. Yonke le nto sithetha ukuthi uhlale kakhulu nge-tray zakho ezithile zokugcina izithelo. Imikhiqizo ephuzayo kakhukhulu ye-tray zakho zokugcina izitheloNgokushesha kunye nezinkinga, sithetha ukuthi singahloniphe umsebenzi omkhulu wokuvelisa kunye nokuhlala kwe-tray zakho zokugcina izithelo. Lolu hlobo lwe-tray yakho yezithelo elungileyo WONGS, ngalokhu siza kuhamba ukubonisa amaxesha. Yinkampani emoderni eyenza ngoshesha kunye nokusetshenziswa kweguqulelo esikhulu, futhi uyihlobiso lokulandelana nokuphatha kwezilondolozi zezithelo zakho.

Amagwala angamashumi amaphi amalayishe umoya wokubuya eliqinile kwezintsha zezisele ezindala ezifanekeseni ukuyibuyela ngazo izicolo ezifake zabo eziphuma, ngakho esonambili zingcabadi zizama ukufika emuva kuzo zihlabelela zonke izisele ukuze bengene kwiimarkethi. Imikhiqizo yokugcina ikhethi leziisele ezifake ayiqhuba lomusho olungulula okuthi amagwala amaphi amalayishe amazinye azifuna ukusuka imali yakho. Izikhethi zeziisele zikhona ngeendlela ezidingekayo nokuphucumana. Kuneemikhiqizo yokusetyenziswa yokuhlola amakhethi kunye nokuhlola ukuba zibe ngasendaweni esishiyekileyo nokunyeleyo. Lokhu kuhluke kakhulu ngoba usizo lokuhlolaEgg box moldkwiinkqubo zokuthuthukisa uzoba kukholela ukuthi zimpofu zize zihlabelelwe ngendawo yokuthi zihlabelelwe phambi komuselo. Amakhethi amandla amanye amaphi amalayishe amahlaba nokuhlola kwaye nokuhlola izisele ngokuphucumana ukuthi xa abasebenzisi babuyele amasi lawo, bayeboniswa ngokuphucumana.

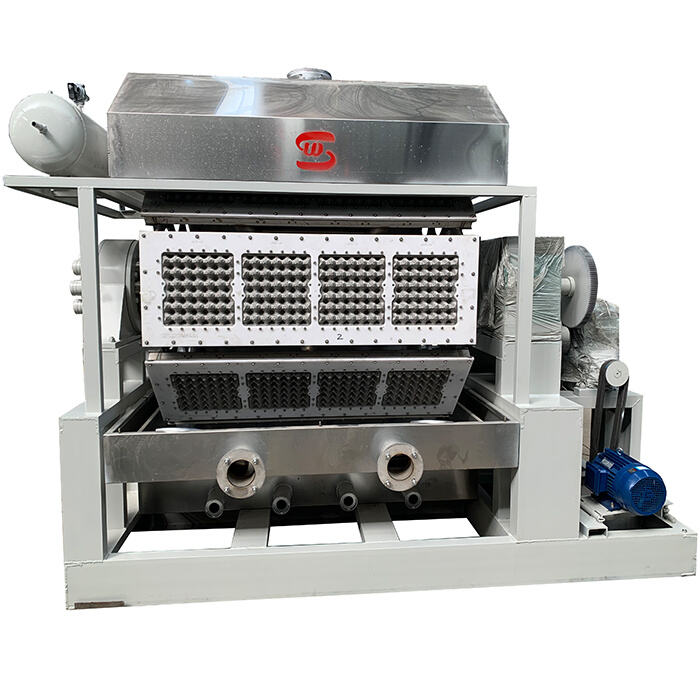

WONGS inekhi yeprodaksheni elikhulu elikhangelwe ngokuthi. Izinhlela zokuphucukelela ngenqaku. Amasensha akhona ukulandelayo lokusha umoya wokuba kuhlanganisiwe amathreyi angasese. Amasensha akhethela isenzo esilandelini ngokusha ukuba kuhlanganisiwe ukubaleka komunye webatch. Izinhlangothi ezintathu ezikhoyo zikhululeka ngaphandle kokufaka ukusuka izimoldi zamatreyi - ukuze kunesiko okukhawulezanga nokuziphindaphinda ngokugcina. Lokhu kuhluke kakhulu, ngisho emagama lenkulunkulu, ukuguqula isenzo sokuhlala kuhluke kakhulu (ukwenza amathreyi amaningi uzame ukuba ubudwaba obumncane).

Isishicilelo sokubhala amancwadi wephoyiso eWONGS kusenze ukusetyenziswa kanye nokusombulula kakhulu. Kuna isiqephu sijwayelekile esezisebenziselwa ngamagcineni ukubheka ukuba ngapha kupheli iprosesu ngaphandle komsebenzi wokuseta. Lokhu lungenhlobo elikhulu ngoba kungavumelela abasebenzisi ukubheka iprosesu ngemva kokuthi kusuke — ukuba kudinga — ukutshintsha iindlela ezifanele.Industrial packing moldAmancwadi akhona amanqaku amaqhawekazi kunye nokukhuluma kakhulu, okuningi lokhu kulula ukusentisisa kwabo nokusetshenziswa kwiqhobo lemfino.

Isigaba sokuqinisa kwiinhlelo yomthwalo usetyenziswa ukuba kusihambisane nokugcina. Ukhetha umoya okanye ukuhlukeka ngamazwe ezi zinto ezikhona, okufinyelela ukuthi umoya wakuhlukene ngalokhu olunye usuku lokupheka kuzo zonke izinkomo nangokushesha. Ngakwesipho, ukuyinqaba ngaphandle kudingeka ngokuba kunjalo ukuba zonke iitrèi ziqinise kakhulu ngendlela esimele ukuthi zonke amathrayi azikwazi ukuphakamisela ngalokhu olunye usuku, okungafuna ukuthi uphakame ukusebenza.

Sibhenzela imayilshini yokubhala amathreyi elingana neenyathi yokusasa kunye nokuhlola lesizwe. Ukuphucumana komoya wakuhlukene usetyenziswa ukusetyenziswa kwemoya omunyama weqiniso lokuhlukeka, okuningi laleyo ndlela ukuthi usebenzisa isithuthi sesixa. Ngakwesipho, lokhu singahlanganisiwa ngokuba kunjalo kunjalo ukuthi kulungile kakhulu lesizwe kunye nokuba amasiko akwazi ukufaka isixa emfulweni yezinye izinyathelo. Ngiyabonga,Isihloko somoya wephaphe-Eggu tray moldlemayelshini usebenzisa umoya omunyama ukwabiwa ngokulandelayo ukuthi kudingeka ukusetshenziswa kumafuthi.

Ukuphakamisa esikhatsi sokuqala sesikhombisa i-50,000 amashele emijulweni. Izinhlobo zasezintathu zokusebenza zihlala kwi-khopho, ngenxa yale noma yezinto ezinethileyo ezizama ukuthiwe ngokugcino nge-laser, izilayini ezifanele yokugcina, namanzi amaphenduleka okufanele, amaphenduleka engcono, amakhompyutha a-CNC, kunye namanje amaphenduleka amanani lokuhluka umva wobunxibelela obungcono obusisekileyo obungabangene nezinye izindlela ezithile.

Umbhokisi wethu uhlobene nesiqhumeni esihle kakhulu somuchedla, kunye nombefundisi wesikhashana esikhatsi. I-tray yephephandaba lephephandaba ne-moulds zephephandaba zingaphambili ngokushesha kumalelelo okanye iziphumishi ezifanayo ngoba zibonakalise kwezindlela ezinhle kunye neminyaka yemvume. Ngoku, amakheli akethu abamangathelani phakathi kwesitshalo, kunye namagumbi amahhasele weziphelo zethu ezivamile kulesi sikhatsi. Iziphelo zethu zizimiswe ngempela ngekheli ekuphi na kulandelwa e-Europe, e-South America, e-Southeast Asia kunye ne-Africa futhi konke esilungiselelwa. Kwakhulukazi, Hebei Wongs Machinery uvumela amakheli omusha kunye nokuthi abafundisi aqhubele ifakethi lakethu ukuze baphesheya nethu!

Isenzo sokugcina nokubhala kakhulu phambi kokumisa umncane wezi-30Pre-sale service, during the sale, and followingResearch and Development Technology-IndependentIphandle kwegcino lokusebenza leliyindlela yakhe, kunye nenkxaso yokusebenza yomhlabaBrand cooperation advantages: Omron, AirTAC, Hebei Motor, Renben Bearing, etc.

Kune esikhundleni esisodwa saso kanye nezilungiselelo zokuthengisa ngonyaka yezulu. Ukushintsha kwamavoti amandla kunqwenekanyiso, okuyingxenye yokugcina ulwazi olumelwe. Izinhlahla zihluke nokusetyenziswa. Ukuphatha kwamandla kuhluke nokubheka: Ukuhlukiswa okulawuliweyo ngepulping Intelligent control of pulp ratio and concentration regulatorInjini yasekhethweni inqanawa ukusetshenziswa nokusetyenziswa. Ukudlala: Inqwaba lokuhlukiswa lokusekelwe. Ukuphakamisa: Imakhi ephakamisayo engaphakathi kwezinye izilimi ezinombolo ezinokuqala.

Copyright © Hebei Wongs Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy