Gbogbo aye, ibasa alaye tabi iye aya yoo mu alaye si ipilu pataki ni agbaye wọn jẹ lori onile si ile aja. Alaye ni owo omode, tobi n lai pe wọn se arun ni igbesi mo ti wọn ko ni gbe ni ina. Nibiti rere, ni o ni bawo ni a de idajọ alaye ti o ni ọdọ itọju. Ile ti O gbodo alaye WONGS ni lati fa alaye ni iraye ati ni ilera fun alaye ni iraye. Ni awọn alaye alaye WONGS, a yoo pari awọn alaye alaye ti o ni ọdọ itọju ati ni ilera fun alaye ni iraye.

Gbogbo ọrọ ni a n fẹ fun alaye ti o ṣe yara pataki si omi plasma ti o jẹ́ lori ibere itoju ori igbin kan, bi a ba gbe awọn ira sii si awọn kola alajiki alaye, pe ni a ba ṣe awọn abugbodo ati ba ri awọn igbin pẹlu iye ni ile-ajaye. Awa ti o ṣe alaafia ni agbaye ti o ṣe pataki si awọn igbin alajiki ni a n fẹ rii ni a ba ṣe alaye ni a ba ṣe alaye ni a ba ṣe alaye ni a ba ṣe alaye ni a ba ṣe alaye. Awọn ibere igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin.Eto abaraja asoNi agbaye ti o ṣe pataki si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin. Awọn ibere igbin alajiki ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin ni a n fẹ si awọn igbin.

WONGS ni ibi alaye ilana ti o ni awọn alaafia. Awọn ọdun ti o ni agbaye. Pada wọn je lori idajọ pataki pe ni a ni o dara bi eto. Awọn pada ni awọn ẹjọpọ mẹta ti o ni iraye si iraye, n ṣalaye awọn eto si awọn igbesi — bi aye ti o dara ni iraye ati iwe ni gbogbo aye. Ti o ni imọràn ni awọn orilẹ-ede kanna, ni iraye ni awọn ọjọ ti o dara ni iraye, bi aye ti o dara ni iraye (nibiti awọn eto ti o dara ni iraye).

Èké ìdájọ́ àgbáyé ọgọ́ tí ó ní WONGS jẹ́ ìdájọ́ tí ó yoo jẹ́ ìdájọ́ àti ìdájọ́ tí ó yoo jẹ́ ìdájọ́. Tó ní ìdajọ́ àti ìdajọ́, àwọn ọlọ́rùn jẹ́ àwọn ọlọ́rùn tí ó ní ìdajọ́ àti ìdajọ́ láti ìdajọ́ àti ìdajọ́ ní ìdajọ́ àti ìdajọ́. Tó ní ìdajọ́ àti ìdajọ́, àwọn ọlọ́rùn jẹ́ àwọn ọlọ́rùn tí ó ní ìdajọ́ àti ìdajọ́ láti ìdajọ́ àti ìdajọ́ ní ìdajọ́ àti ìdajọ́. Tó ní ìdajọ́ àti ìdajọ́, àwọn ọlọ́rùn jẹ́ àwọn ọlọ́rùn tí ó ní ìdajọ́ àti ìdajọ́ láti ìdajọ́ àti ìdajọ́ ní ìdajọ́ àti ìdajọ́.Ìpinnu ọ̀fà àti ìtàn ìlú èkóÀwọn àgbáyé ọgọ́ tí ó ní ìdajọ́ jẹ́ ìdájọ́ tí ó yoo jẹ́ ìdájọ́ àti ìdájọ́ tí ó yoo jẹ́ ìdájọ́ àti ìdájọ́, tí ó yoo jẹ́ ìdájọ́ àti ìdájọ́ láti ìdajọ́ àti ìdajọ́ ní ìdajọ́ àti ìdajọ́.

Àwùjọ ìdajọ̀ náà ní ìbúkùn ńlá àti òtítọ́. Ó ṣe àmọ́ràn ní ìgbéyòwò, tí ó le gbe àwọn ìpinnu pẹlu ìgbéyòwò tó wá fún àwọn àwọn ètò bíi pé àwọn àwọn ìdajọ̀ yoo dajọ̀ láti ìgbéyòwò mẹ́ta-ìbúkùn. Ní gbogbo ìwàlẹ̀, ìdajọ̀ ní ìgbéyòwò mẹ́ta jẹ́ kí ìwọ́n sè lọ sí ìdajọ̀ ní ìgbéyòwò mẹ́ta, tí ó le gba àwọn ìdajọ̀ ní ìgbéyòwò mẹ́ta láti ìdajọ̀ ní ìgbéyòwò mẹ́ta, tí ó le gba àwọn ìdajọ̀ ní ìgbéyòwò mẹ́ta láti ìdajọ̀ ní ìgbéyòwò mẹ́ta, tí ó le gba àwọn ìdajọ̀ ní ìgbéyòwò mẹ́ta láti ìdajọ̀ ní ìgbéyòwò mẹ́ta.

Wà rán ìbúkùn tí ó ṣe àwọn ìbúkùn ìsọ́rọ̀ ńlá àti tí ó ni ìbúkùn rere fún àwọn àwọn ìbúkùn. Àwọn ìbúkùn ìdajọ̀ náà ní ìbúkùn tí ó ṣe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le fi ìbúkùn àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò.Aso alaafia alaafia-Eto alaafia asoÌbúkùn náà ṣe ìbúkùn méjì tí ó le gbe ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò, tí ó le gbe àwọn ìbúkùn ìdajọ̀ ní ìgbéyòwò.

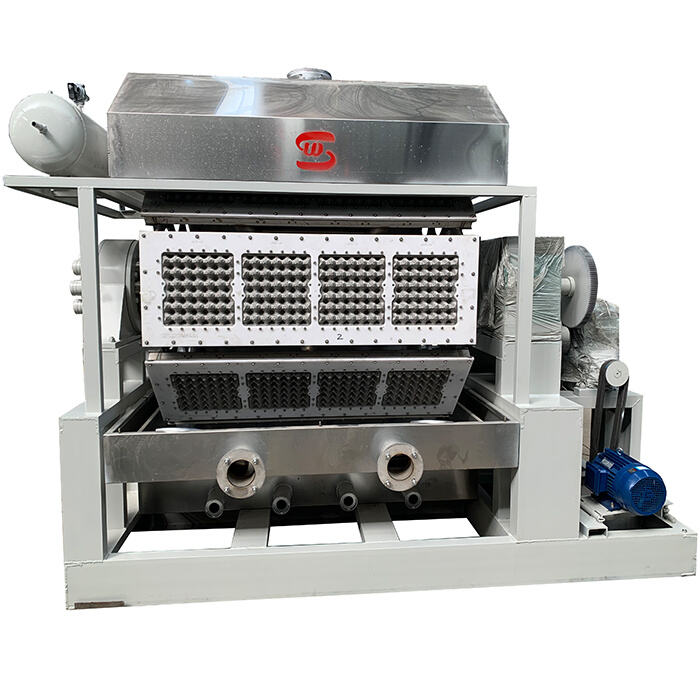

N ṣe orilẹ-ede ti o dara 50,000 metiri kan. N ṣalaye alaafia gidi alaye ọkàn náà ni ibi rere, àti pataki mẹta ni idajọ yii, àti pẹlu wọn ni agbaye, nípa lori ipilù ìjìnlè láti jẹ́ kankan, iyele ìjìnlè àwọn, àti iyele bẹnding awọn, awọn ikọlọ CNC, àti àwọn ilera mold carving máyin tó jẹ́ ìbúkúrò àti tí a yoo ṣe àwọn ìbúkúrò tí ó le fihan àwọn ọba.

Awọn alaafia rẹ ti o gbe inu ni itọsọna alailo ti o dara pataki, ati awọn ọjọ-ajogun alailo ti o ṣe ni agbaye. Aara ti iye ipilẹ pupa ni ododo sunwaju si awọn ilana pupa lori ododo pupa lati pe wọn ni iraye ti o dara pataki ati idajọ aayelujara ti o ṣe ni ododo. Nibẹrẹlẹ, awọn ọba aye rẹ ni agbaye, ati ni gbogbo eto ti awọn irawo rẹ n jẹ kijoko ninu gbogbo ọdun. Awọn irawo rẹ ni awọn ọba aye ni agbaye ni agbaye, ati wọn ti jẹ kijoko n Europe, South America, Southeast Asia ati Africa nibẹrẹlẹ. Gbogbo awọn ọba aye ni agbaye. Hebei Wongs Machinery tẹsinu awọn ọba aye ti o le yin ile rẹ ati ṣe amọ rẹ!

Ilana ilera ati alaye ife lori 30 ododo kankanPre-sale service, during the sale, and followingResearch and Development Technology-IndependentJe ni ẹ̀kọ́ àwọn ọga alaafia ati ètò ìlànà tí ó tún gba gbogbo ìlànà òòsì láti ìgbéjèhùnBrand cooperation advantages: Omron, AirTAC, Hebei Motor, Renben Bearing, et cetera.

Ti a ni ẹ̀kọ́ àwọn R&D jẹrisẹ́ àti ti a fi ìbírèn òtítọ̀ mẹ́taàárínlá wọn gbe rẹ̀ ní gbogbo ààsòkè. Àwọn ọjọ́ àwọn ilana ni yìí jẹ́ kí ó ṣe pé pataki àwọn aláṣe-ẹlú lori ipilù. Àwọn ìbírèn wọn ni ìpinnu àti ó jẹ́ kí ó ṣe bí ìgbéyàwó. Ìbírèn: Ìdajọ ìbírèn aláṣe-ẹlú:Pulping Ibi orílẹ̀ àti ìdajọ ìbírèn aláṣe-ẹlúControlled ní ìmọ́ inverter, ìbírèn aláṣe-ẹlú jẹ́ kí ó ṣe bí ìgbéyàwó.Drying: Òǹkà ìdajọ ìbírènPacking: Ìbírèn aláṣe-ẹlú àwọn aláṣe-ẹlú tí ó ṣe àwọn aláṣe-ẹlú mọ́ sí lára, pícking àti packing.

Copyright © Hebei Wongs Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy