Шляхом сушіння та стиску паперу у формі для листкового формування: це дивовижна технологія для виготовлення подонків і контейнерів з перероблених паперів. Як відповідальна, екологічно орієнтована компанія, WONGS стає дуже популярною завдяки своїй впевеності в галузі. Ця стаття розповість вам про революційну систему сушіння формованого листка і чому ви можете виготовляти чудові подонки, використовуючи її, як ця система перевага для людей і допомагає їм працювати швидше ніколи досі.

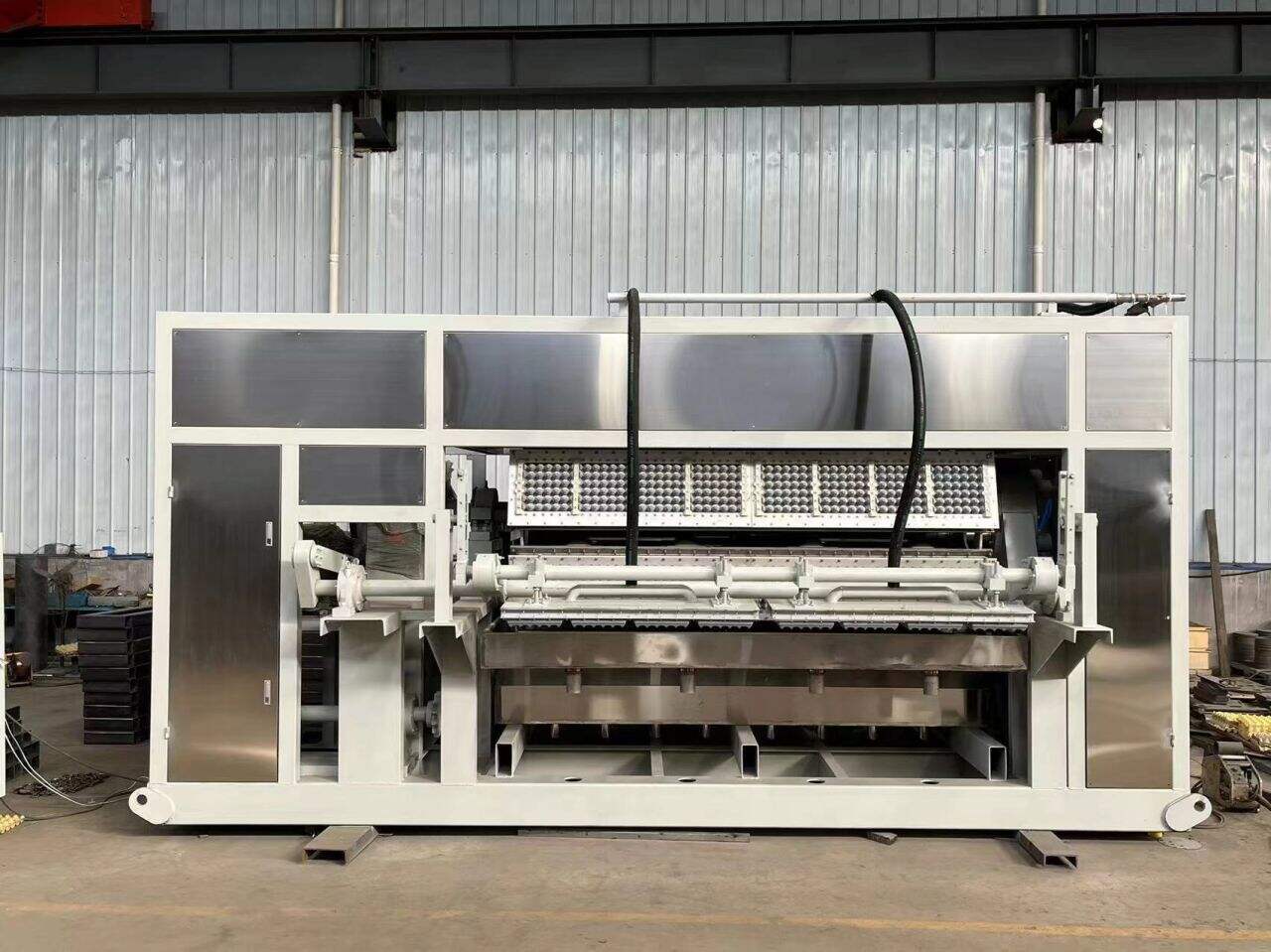

Одним із найкращих способів зниження витрат на виробництво є розробка Форма для формування паперової маси - форма для подонків під яйця системи сушіння, яка сушить подонки швидше і краще, ніж інші старі методи. Вона використовує гарячий повітря для сушіння формованих подонків. Іншими словами, це означає, що подонки можуть бути підготовлені набагато швидше і мають кращу якість. Ця технологія дозволяє компаніям виготовляти більше подонків за менший час, що дозволяє їм виробляти менше інструментів для всіх своїх клієнтів.

Сушка є дуже важливою після формування хорошого подову. Якщо подови не просихають відповідно, вони можуть бути недостатньо міцними для підтримки предметів, які ви використовуєте. Це схоже на те, коли ви печете торт — якщо витягнути його занадто рано, він може розвалитися. Процес сушку забезпечує те, що подови зберігають свою форму і цілісність, дозволяючи безпечно і надійно переносити продукцію. За допомогою унікальної системи WONGS вони удосконалили цей процес сушки, щоб кожен подов був створений для тривалого використання.

Зараз ви, мабуть, думаєте, чому використовувати систему сушку і гаряче пресування паперових подов. По-перше, вона екологічна — подови виготовлені з переробленого паперу. Це зменшує парникові гази, захищає нашу планету і є витратно ефективним, що швидко робить її операційно придатною для бізнесу. По-друге, ця система забезпечує високу швидкість виробництва подов порівняно з попередніми системами, оскільки всі секції охолодження мають унікальну форму, що дозволяє повітрю протікати з більшою швидкістю. Технологія WONGS робить це Форма для коробок під яйця подноси швидко виготовляються з високою ефективністю. Нарешті, система ефективна у виготовленні міцних і надійних підносів, які можуть запобігти будь-якому виду пошкодження вашої продукції під час її доставки. Це гарантує компаніям, що їх продукція дістанеться до точки продажу в чудовому стані.

Нам потрібен добрий штурм і гаряче пресування, щоб завершити багато підносів за короткий час. КОМПАНІЯ WONGS використовує свою унікальну систему для переміщення виготовлених підносів швидше, ніж колись раніше. Система складних підносів підтвердила, що підноси були міцними і здатними нести те, що вони мають містити. Швидке сушування і гаряче пресування дозволяє підприємствам доставляти продукцію високого якості своїм клієнтам учасково. Вона повинна бути надійною, щоб підприємства, які її використовують, могли задовольняти своїх клієнтів і здобувати повторні замовлення.

Процес виготовлення подів і контейнерів великою мірою залежить від використання технології формування паперової маси та її сушки. Ця технологія допомагає правильно формувати поди і забезпечує швидке їх просusку, щоб зберегти їхню міцність. Поди не зможуть тримати продукти, для яких призначені, якщо формування паперової маси та її сушка виконані неправильно. Вони розробили передову Форма для держача кавових чашок та технологію сушки, яка дуже ефективна в галузі і дозволяє компаніям створювати натуральні білкові продукти просто й легко.

У нас є незалежна команда РД та ми постійно оновлюємо наше обладнання протягом року. Процес виробництва автоматизований і зменшує вартість праці. Обладнання безпечне і просте в експлуатації. Інтелектуальна система керування обладнанням. Переробка: Регулятор концентрації, інтелектуальне керування співвідношенням пюре. Керується інвертором, формуюча машина проста у управлінні та експлуатації. Сушка: Контролер температури. Упаковка: Автоматична упаковна машина, яка використовує одну лінію для лічби, вибору та упаковки.

Наша компанія — це добре встановлена мережа продажів та професійна служба післяпродажного обслуговування. На основі нашого унікального досвіду та технологій, лінія виробництва паперової бумажної тари та форми для паперової маси виділяються серед подібних продуктів. Зараз наші клієнти знаходяться у різних кутах країни, а кількість експортних поставок продукції також зростає кожен рік. Наші продукти набувають все більшої популярності серед клієнтів і експортується до Європи, Південної Америки, Південної Азії та Африки тощо. Компанія Hebei Wongs Machinery вітає нових та поточних клієнтів, щоб вони приїхали до нашого заводу для обговорення бізнесу!

Розмір території становить 50,000 квадратних метрів. Є три виробничі майстерні та цех фарбування. Наша компанія зробила інвестиції в повністю автоматизовані лазерні лінії, повністю автоматизовані різальні лінії, повністю автоматизоване обладнання для гинання, ЦНУ обробний центр та кілька машин для гравювання форм, щоб виробляти більш досконале обладнання та добре обслуговувати кожного клієнта.

Досвід виробництва і виробництва протягом 30 років Допродажовий, під час продажу та післяпродажовий сервіс Технології для незалежного дослідження та розробки Власний відділ післяпродажового обслуговування та глобальна технічна підтримка Переваги співпраці з бренда: Omron, AirTAC, Hebei Motor, Renben Bearing тощо.

Всі права захищені. © Hebei Wongs Machinery Equipment Co.,Ltd - Політика конфіденційності